Here are a couple of photos.

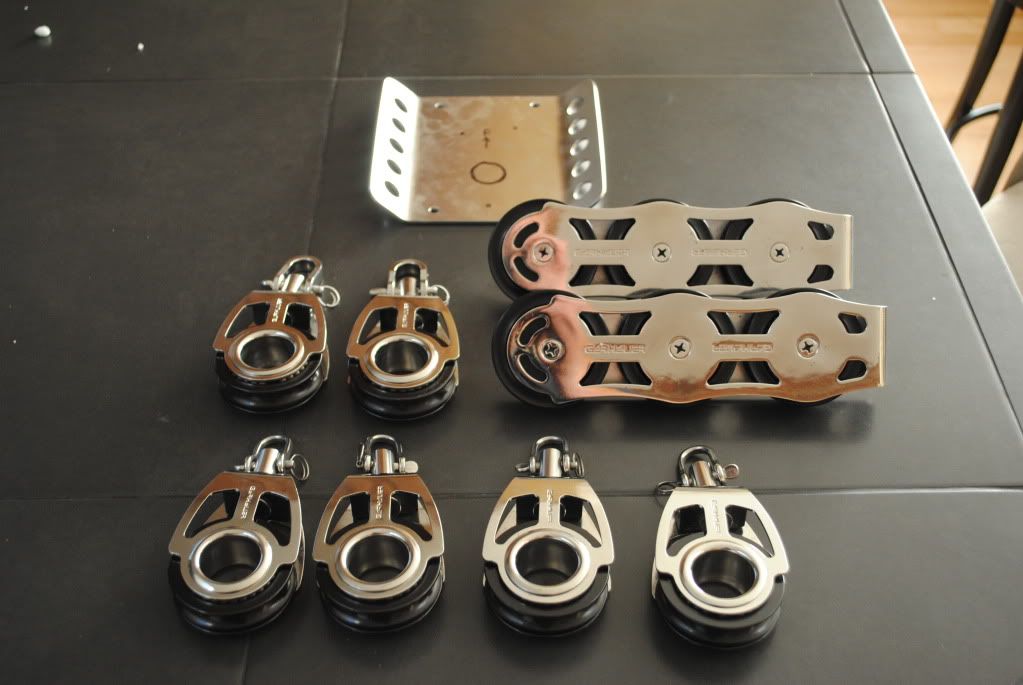

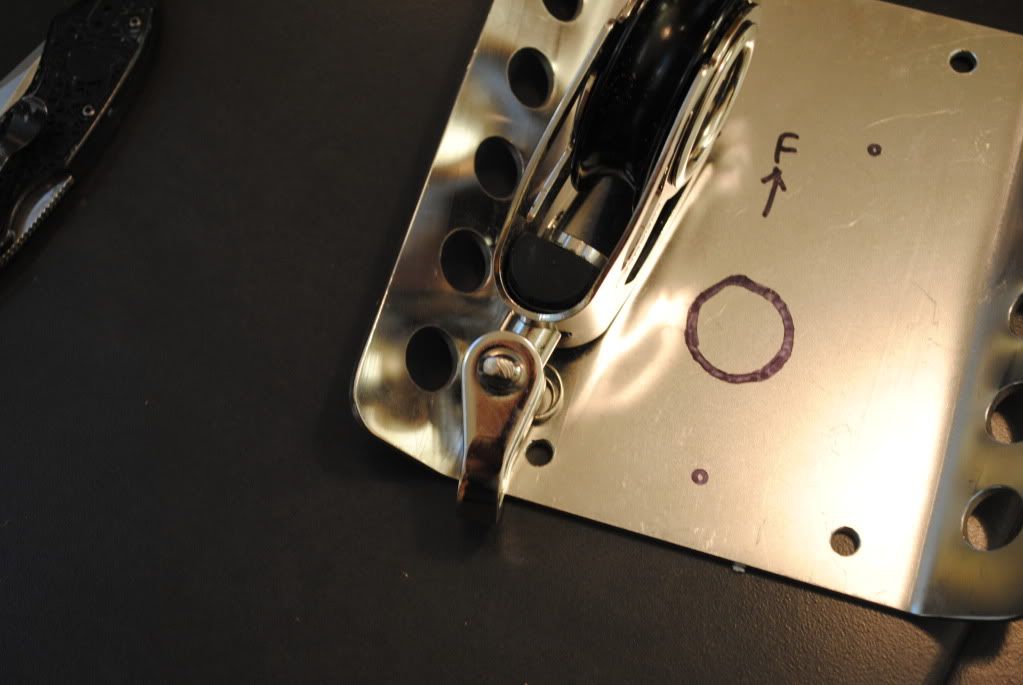

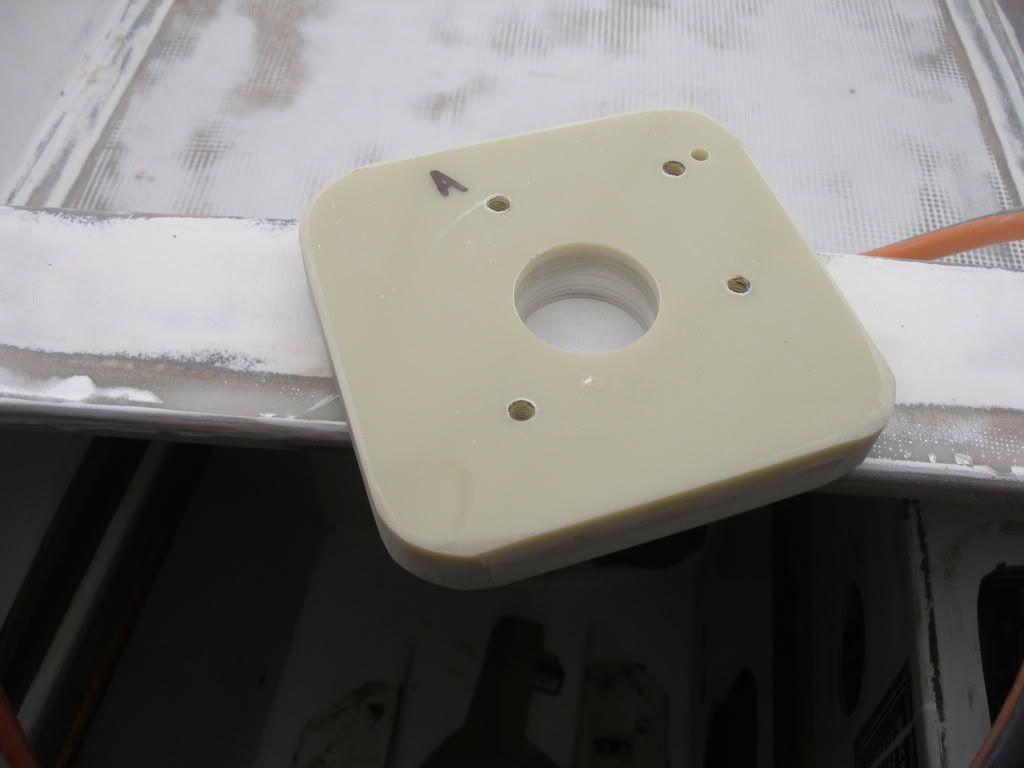

Here is a shot of the massive backing plate for the sink drain seacock/adaptor. I epoxied two 1/2 inch thick pieces of G10 together to get almost 1 inch of thread depth. Obviously this is way overkill. The two holes in the upper right corner are my test holes. I tried tightening a bolt into the threaded one with as much force as I could muster and the threads held fine. So I figure it will be strong enough.

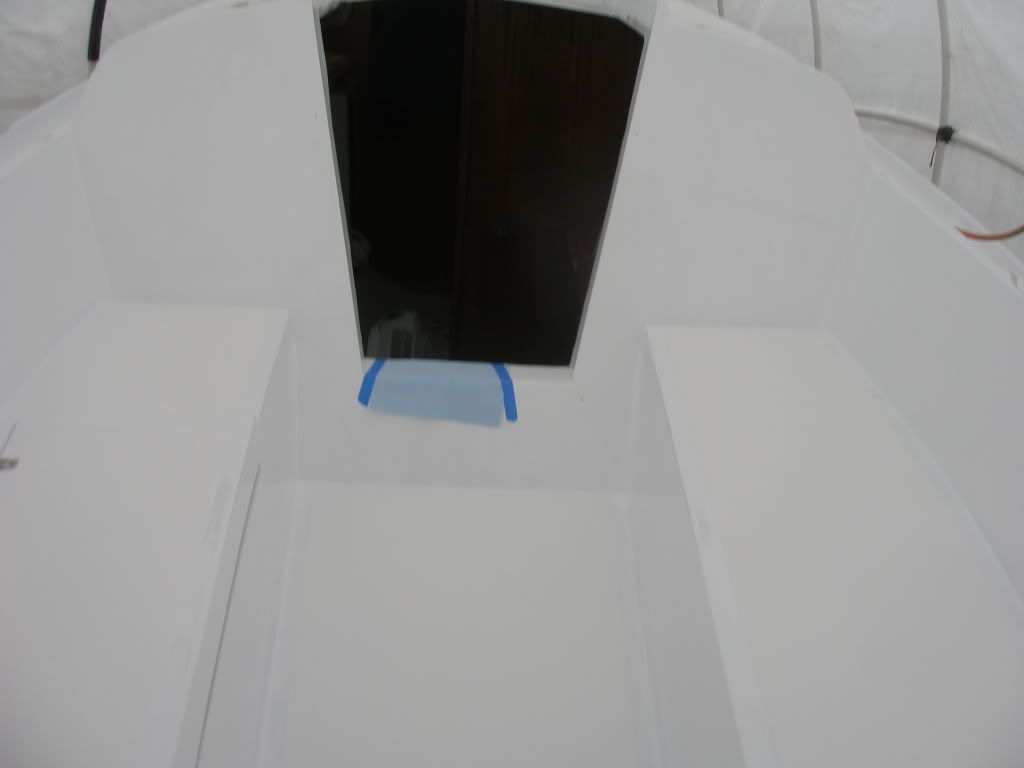

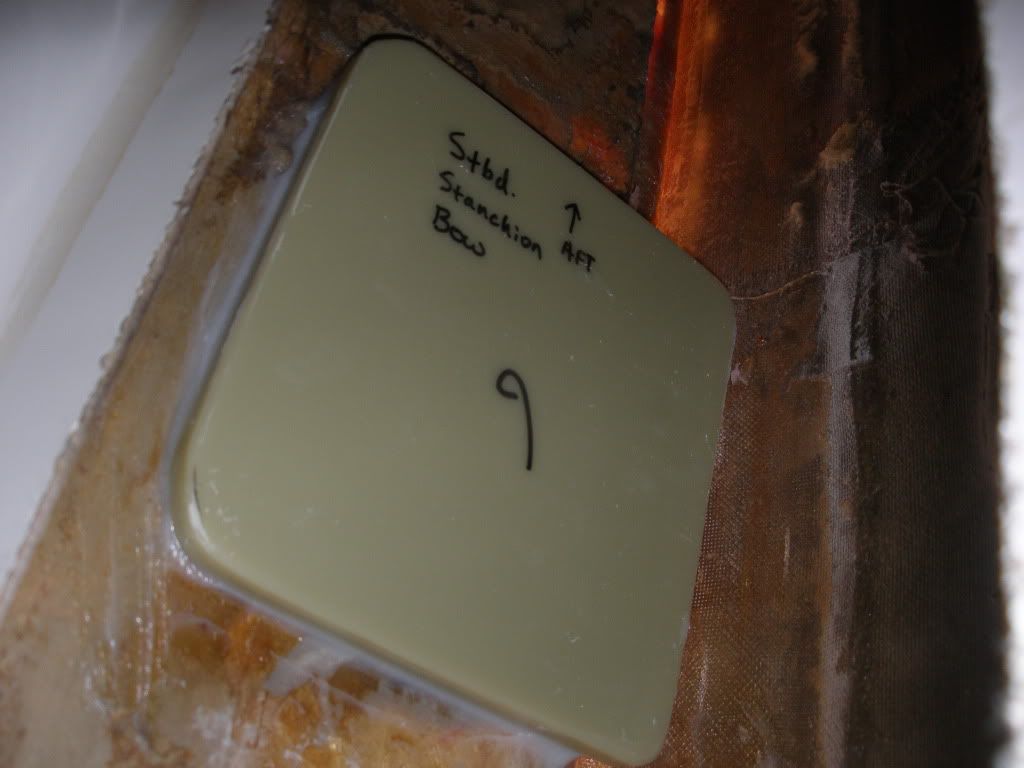

Here is the installation. I had to twist the plate around a little more than I wanted to get a good alignment on the thru-hull.

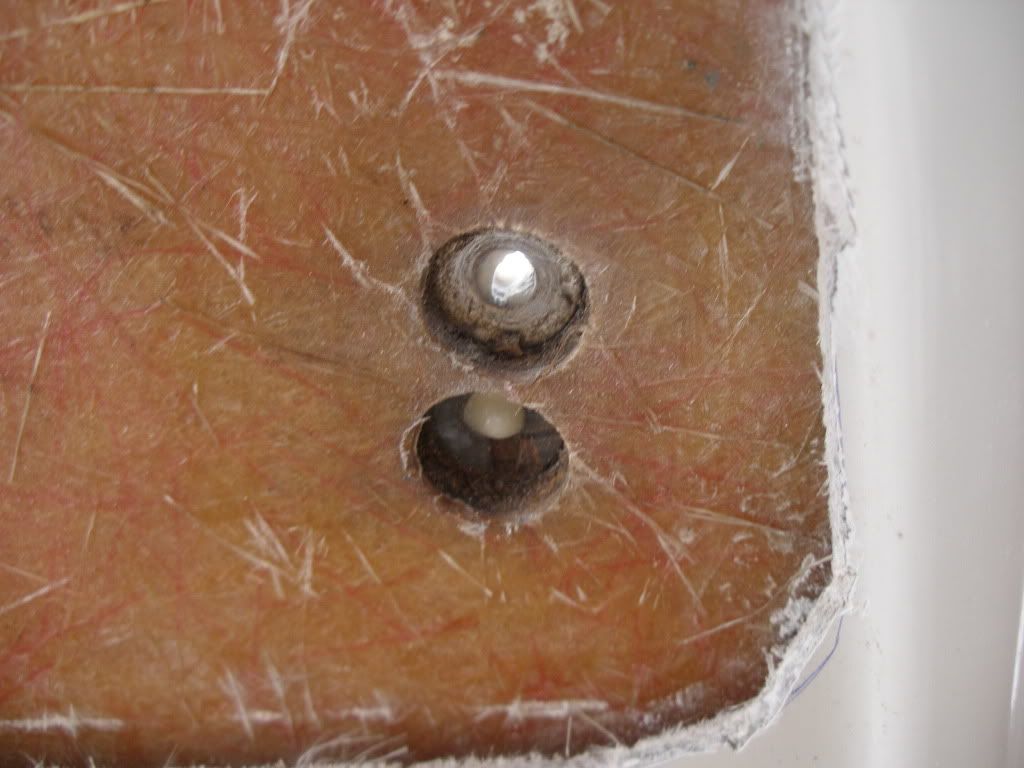

Here is one of the backing plates. If this comes out its taking half the deck with it...

I also glassed in a couple of braces made from scrap mahogany for a platform to hold a fuel tank under the cockpit. I sealed them with epoxy before installing them.

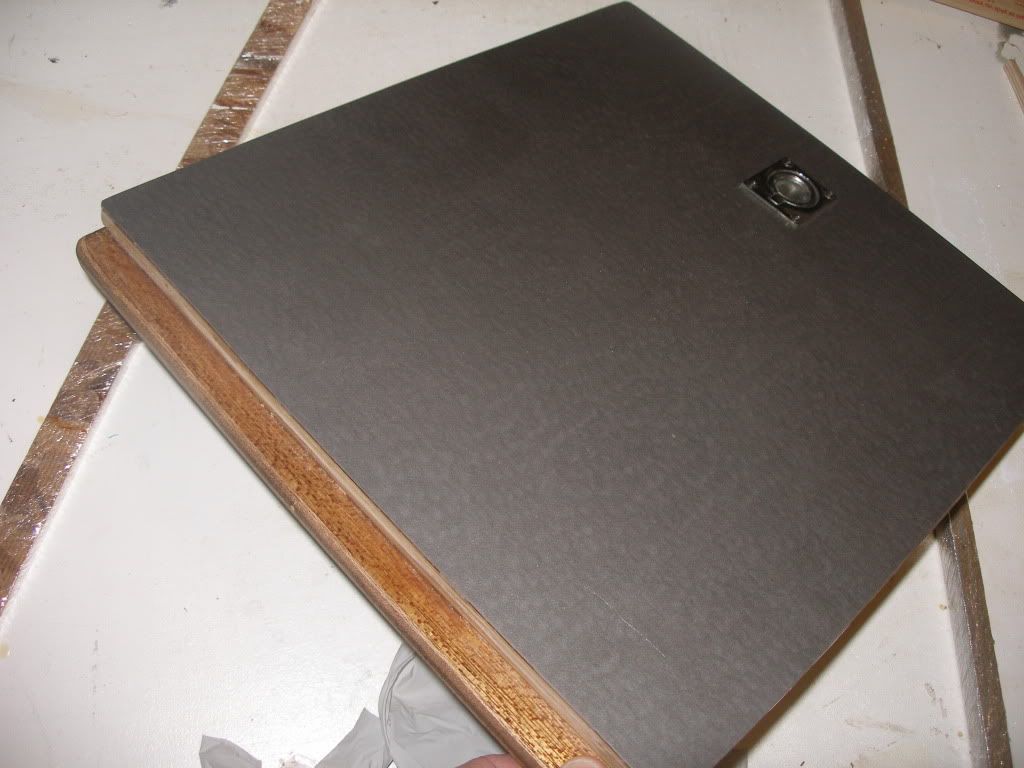

And finally I started working on repairing the old engine compartment and preparing a battery platform using a bunch of scrap materials I had lying around. The plan is to place two batteries along the centerline, each in a plastic battery box, and strap them to the old engine beds. The plywood panel (which I glassed on both sides some years ago as a test for some other project) will be removable to be able to clean underneath.

Next task- Cutting the glassed-in chainplates off- the prospect of which has caused more than a few sleepless nights and much hemming and hawing. However, once that is done, there will be no more major glass-work, a major milestone. Then I can think about painting again, just in time for warmer weather. But that's a month or more down the road... And in between now and then I need someone knowledgeable to inspect the mast which has some dimples/compression damage around the spreaders along with some extra holes and an oversized compression bolt hole.

More next weekend hopefully.