I am finally working on the Corinthian - the first task is to get the hull sound. Three things jumped out as needing some glass/epoxy work:

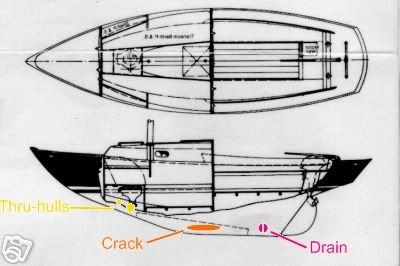

- Installing a garboard plug (there was none before, and the boat had sat on the hard, full of water, for an indeterminate number of years - I had the yard drill a 1" hole after the first day I saw it)

- Removal of the head, and sealing the thru-hulls. (Anybody need a vintage head? - a real collector's item!)

- Investigation of a crack in the ballast area, which was weeping moisture even after the bilge was drained to about 2".

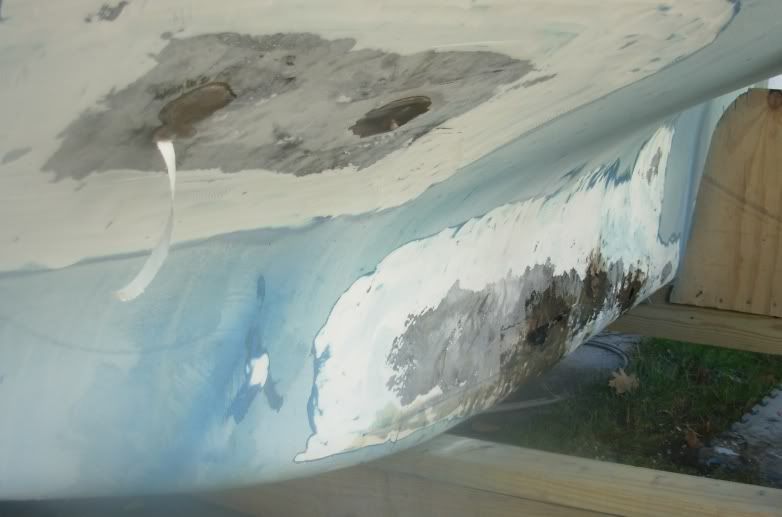

This last item turns out to be a problem. I cut away the bottom paint and gel coat (using the nifty Ryobi 18V planer - minimal dust!) and found that there is a void around the lead, maybe 1/2 wide at this point, with a significant amount of un-resined fiber inside. Presumably this void has been full of water for 20 or 30 or 40 years.

Anybody encountered this? Any suggestions? I am thinking about a second garboard drain, or an inside drain from the ballast to the bilge, or simply filling the void with something - epoxy? concrete?

Thanks a million!