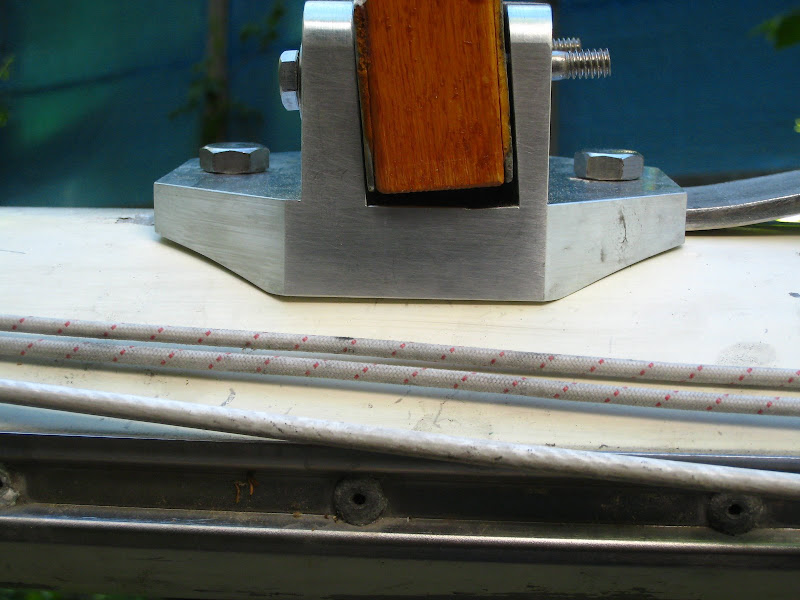

I found a crack in one of my cast aluminum spreader brackets so I had a new pair machined out of 7075 aluminum. The new ones are cut to fit the oak spreader bars in the same basic shape as the old brackets, except they are thicker and should be much stronger.

One nagging issue is that the spreader bars don't touch the back of the bracket. It was the same on the originals, so I dismissed it not wanting to re-engineer the part. Now it is bugging me a little. I'm packaging up the mast for transport and took another look at the brackets. I'm thinking the rig would be stronger if the bar were to rest on the back of the bracket so all the inward forces from the stay would go right to the mast. The way it is now, the force is directed to the fasteneres (1/4 inch steel bolts) that go through the bracket and spreader bar. Compression rather than sheer.

I'll get a picture this morning and post.

-Jeff

Basic Rigging Question

- preserved_killick

- Skilled Systems Installer

- Posts: 220

- Joined: Wed Oct 24, 2007 8:01 am

- Boat Name: Seagrass

- Boat Type: Alberg 30

- Location: NH

- Contact:

- preserved_killick

- Skilled Systems Installer

- Posts: 220

- Joined: Wed Oct 24, 2007 8:01 am

- Boat Name: Seagrass

- Boat Type: Alberg 30

- Location: NH

- Contact:

Re: Basic Rigging Question

I'm launching at the end of the week so I think what I'll do is extend the spreader bar by building a mold onto the end of each spreader, then pour some epoxy thickened with some colloidal silica. Once cured, I'll sand shape to fit the bracket. I wish I were better at molding epoxy. I great solution would be to pour some very thickened epoxy into the bracket, and then put the spreader in place. I've tried a similar projects in the past, but it never comes out right. Perhaps a better release agent.

Here are pics of the old and new bracket.

Couple recent pics of the boat since I'm at it (and avoiding my real job):

http://picasaweb.google.com/fongemie/Bo ... directlink

Here are pics of the old and new bracket.

Couple recent pics of the boat since I'm at it (and avoiding my real job):

http://picasaweb.google.com/fongemie/Bo ... directlink

- Chris Campbell

- Candidate for Boat-Obsession Medal

- Posts: 422

- Joined: Tue Jun 06, 2006 9:18 am

- Boat Name: Luna

- Boat Type: Yankee 30

- Location: Chester, NS

- Contact:

Re: Basic Rigging Question

Wow! Your boat looks beautiful - great job on the brightwork!

I'm sure others will have more to say about the spreader socket, but here's my opinion (free, and worth every penny!): the new socket looks stronger than the old, and the old way worked for how many years? I wouldn't worry about it. I also suspect there might have been a reason for letting the fasteners take the load, although I can't imagine what it might be. Do the fastener holes in the spreaders show any sign of deformation? If no, then surely everything is strong enough. If yes, perhaps just filling them with thickened epoxy and re-drilling would be sufficient? That way you also avoid re-designing something, which is sometimes for the best.

I'll be curious to hear what others have to say - and maybe about what others' spreader sockets look like.

Cheers,

Chris

I'm sure others will have more to say about the spreader socket, but here's my opinion (free, and worth every penny!): the new socket looks stronger than the old, and the old way worked for how many years? I wouldn't worry about it. I also suspect there might have been a reason for letting the fasteners take the load, although I can't imagine what it might be. Do the fastener holes in the spreaders show any sign of deformation? If no, then surely everything is strong enough. If yes, perhaps just filling them with thickened epoxy and re-drilling would be sufficient? That way you also avoid re-designing something, which is sometimes for the best.

I'll be curious to hear what others have to say - and maybe about what others' spreader sockets look like.

Cheers,

Chris

-

baysailer

- Bottom Sanding Grunt

- Posts: 8

- Joined: Thu Apr 30, 2009 11:36 am

- Boat Name: Ms.Anne

- Boat Type: Pearson Triton #662

- Location: Gloucester Va

Re: Basic Rigging Question

Captain, mighty handsome vessel.Attention to all the details,one could only hope that their own (me included)turns out as nice.Have many good days aboard her,I would .Baysailer

-

Hirilondë

- Master of the Arcane

- Posts: 1317

- Joined: Thu Dec 28, 2006 8:50 am

- Boat Name: Hirilondë

- Boat Type: 1967 Pearson Renegade

- Location: Charlestown, RI

Re: Basic Rigging Question

The gap is intentional. If it were tight to the mast or bracket then moisture would be trapped all the time. Leaving the gap allows it to stay dry.

Don't fix it, it ain't broke.

Don't fix it, it ain't broke.

Dave Finnegan

builder of Spindrift 9N #521 'Wingë'

--------------------------------------------------------------------------------------------------------------------------------------------------------------------

Gresham’s Law of information: Bad information drives out good. No matter how long ago a correction for a particular error may have appeared in print or online, it never seems to catch up with the ever-widening distribution of the error.

builder of Spindrift 9N #521 'Wingë'

--------------------------------------------------------------------------------------------------------------------------------------------------------------------

Gresham’s Law of information: Bad information drives out good. No matter how long ago a correction for a particular error may have appeared in print or online, it never seems to catch up with the ever-widening distribution of the error.

- catamount

- Candidate for Boat-Obsession Medal

- Posts: 378

- Joined: Sun Jun 19, 2005 7:30 am

- Boat Name: GREYHAWK

- Boat Type: Peterson 34

- Location: Boothbay Harbor, ME

- Contact:

Re: Basic Rigging Question

Thread jump: So who did you get to truck the boat?preserved_killick wrote:I'm launching at the end of the week

BTW, looks good! She'll really put the rest of the mooring field to shame ;-)

Tim Allen -- 1980 Peterson 34 GREYHAWK

Harborfields Housekeeping Cottages, West Boothbay Harbor, Maine

Sailors for the Sea, a new voice for ocean conservation

Harborfields Housekeeping Cottages, West Boothbay Harbor, Maine

Sailors for the Sea, a new voice for ocean conservation

- preserved_killick

- Skilled Systems Installer

- Posts: 220

- Joined: Wed Oct 24, 2007 8:01 am

- Boat Name: Seagrass

- Boat Type: Alberg 30

- Location: NH

- Contact:

Re: Basic Rigging Question

Thanks Tim.

We're using Coastal Boat Transport out of Newcastle, ME. They were available, we'll see.

-jeff

We're using Coastal Boat Transport out of Newcastle, ME. They were available, we'll see.

-jeff