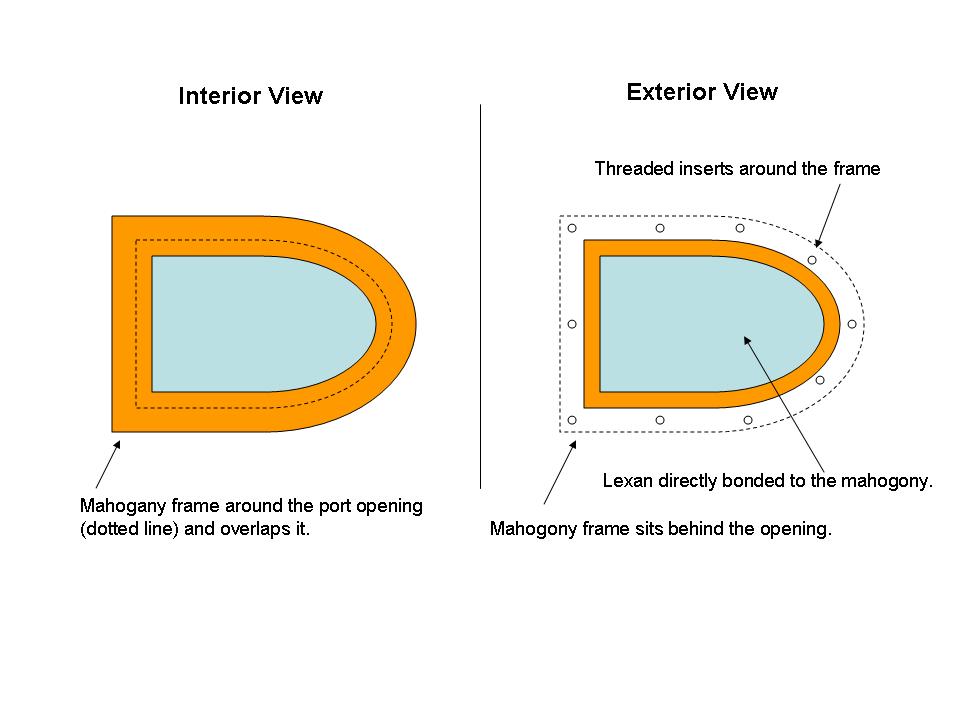

As you might know the west coast Tritons have large fixed ports in the main cabin that are mounted on the exterior. It does not match my personal preferrence although it is a very strong installation. I have thought of different ways to address that issue including buying bronze port frames like the east coast Tritons but they are very expensive. So, my thoughts are now revolving around moving the fixed glasses (polycarbonate or in my case Lexan) to the interior of the cabine as the attached diagram illustrates. I would still use barrel bolts to fasten the glass to the cabin for strength. I was also inspired by Dave's approach to building an interior woord frame for the glass (see picture from Dave's Renegade which I have droolled over many a times).

I would very much appreciate your ideas, thoughts, and comments to this approach.