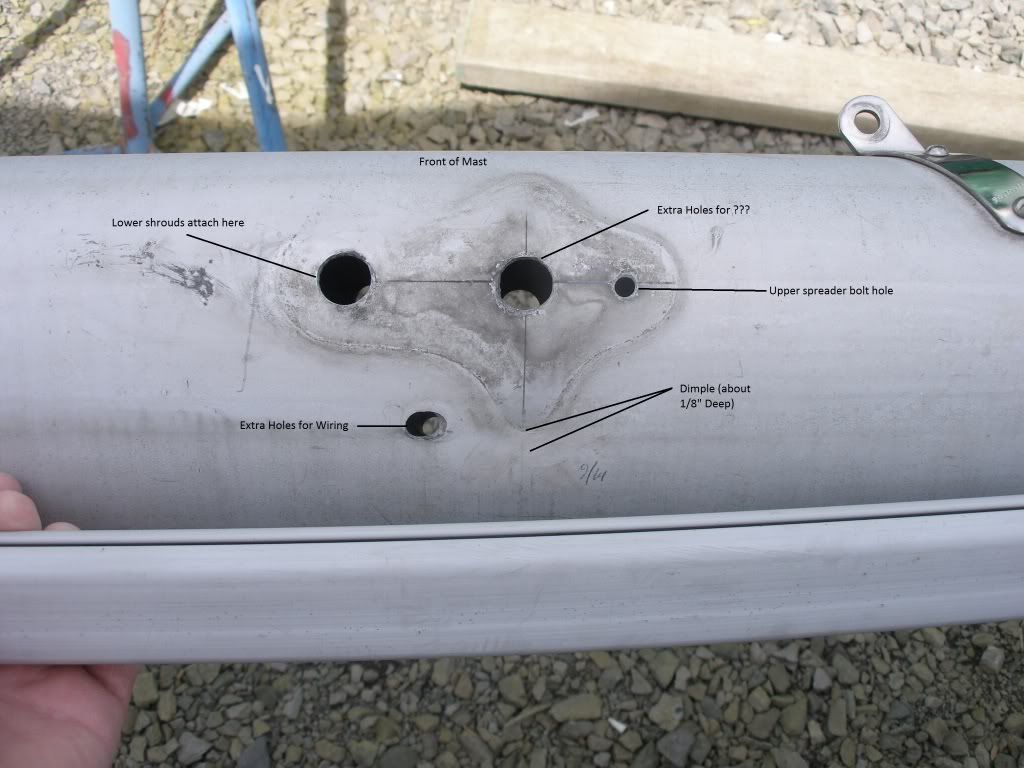

Here is a shot of the area, with some notes on the different features.

Here is the mast profile. The aft wall between the main compartment and the sail track is near the dimpled portion of the mast.

So I have been thinking about putting two big reinforcing patches over each side of the entire affected area and then redrilling only the necessary holes. I have heard that it might be wise to make this in an elongated triangular fashion (tapered up and down the mast) so as not to create a hard point right above or below the patch. Also, this guy here http://home.comcast.net/~ericson-yachts ... epair.html repaired it using a big exterior sleeve, but had some trouble, so I am not sure that is the way to go.

Any advice?

Thanks!

Doug