Just hauled my Triton 106 Blossom out at the local Svendsens Boat Yard. There are five large and small jobs that I planned for this haulout:

1. Strip the bottom paint down to the gelcoat (I have a separate post with a question on stripping)

2. Inspect and repair rudder, shaft if needed

3. Replace three ball valves with seacocks (two cockpit drains, one engine inlet)

4. Remove depthsounder transducer and patch the hole (I have installed another inhull ducer)

5. Remove the seacock in the head (under the vanity sink) and patch the hole (I don't plan to use it)

This question has to do with the first job. After I remove the rudder and rudder post I cleaned the rudder shaft to inspect it. I found extensive pink condition, espcially along the part that sits inside the rudder post and the part that contact the rudder. I am planning to replace it with another bronze shaft. My question is what is the best design for a new shaft.

I thought of two options:

1. The original design, simple and proven to have worked for fifty years (Blossom was built in 1959)

2. To the original design add two ears as Tim did on Glissando (strengthens the original design)

Chris at the metal shop at Svendsens is emphatic that welding will significantly weaken the shaft and introduce electrolysis. What is your experience?

Another local Triton owner just rebuilt his shaft and did not use lag bolts as the original design. He welded a large ear along the entire length of the shaft where it contacts the rudder. The ears are basically two 1/8" bronze plates welded separately to the shaft. He went out on the SF Bay in near gale condition yesterday and lost his rudder. He had to be towed in by a friend. His experience is causing considerable anxiety in my mind. We don't know what went wrong but one of the possible reasons is that the welding failed. This is causing me to think more than twice what Chris at Svendsens said about welding bronze causes weak spots.

Triton Rudder Shaft

-

Triton106

- Candidate for Boat-Obsession Medal

- Posts: 392

- Joined: Fri Apr 18, 2003 4:51 pm

- Location: San Francisco Bay Area

Triton Rudder Shaft

Ray D. Chang

Triton 106 in Berkeley, CA

Triton 106 in Berkeley, CA

-

Triton106

- Candidate for Boat-Obsession Medal

- Posts: 392

- Joined: Fri Apr 18, 2003 4:51 pm

- Location: San Francisco Bay Area

Re: Triton Rudder Shaft

A quick update.

My decision on rudder shaft design has been postponed by the kindness of another Triton owner who kindly gave me his old rudder and shaft. It appears to be in servicable condition after I cleaned it up and examined the shaft. The shaft shows some pink signs of corrosions but overall condition is acceptable for a couple of seasons of service. That will give me time to properly think through the design and rebuilding of my own rudder.

My decision on rudder shaft design has been postponed by the kindness of another Triton owner who kindly gave me his old rudder and shaft. It appears to be in servicable condition after I cleaned it up and examined the shaft. The shaft shows some pink signs of corrosions but overall condition is acceptable for a couple of seasons of service. That will give me time to properly think through the design and rebuilding of my own rudder.

Ray D. Chang

Triton 106 in Berkeley, CA

Triton 106 in Berkeley, CA

-

Duncan

- Candidate for Boat-Obsession Medal

- Posts: 388

- Joined: Fri Mar 03, 2006 7:28 am

- Boat Name: Coquine

- Boat Type: Cape Dory 27

- Location: Montréal

- Contact:

Re: Triton Rudder Shaft

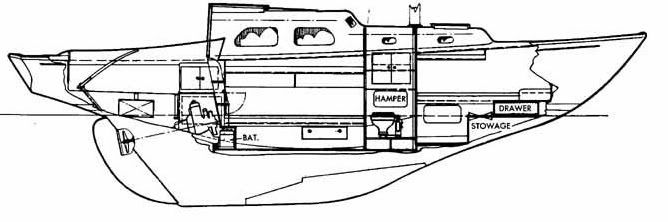

Now that you've got time to think about it, here's an alternative rudder arrangement Fred Bickum came up with on a very similar Alberg boat (Cape Dory 28) - CD28 Fenix Rudder.Triton106 wrote:...That will give me time to properly think through the design and rebuilding of my own rudder.

It's a more complex project, but he circumnavigated with this new arrangement, so that was a good test of it!

Cape Dory 10 & 27

Re: Triton Rudder Shaft

I've looked at Fred's rudder design in the past. His whole re-fit was fun to watch and read about. I don't know that I'd go with it myself, because I'm just so used to the relative security of having the rudder be one with the keel; but on the other hand I bet it made for nice steering!

One thing I wonder though: The transom/stern area on a CD 28 is pretty "chunky" compared to a Triton. I'm sure anything can be done to anything, but I wonder if it would work out anywhere near as well or easily on a Triton with it's more svelte shape in that area? What do you think?

Rachel

One thing I wonder though: The transom/stern area on a CD 28 is pretty "chunky" compared to a Triton. I'm sure anything can be done to anything, but I wonder if it would work out anywhere near as well or easily on a Triton with it's more svelte shape in that area? What do you think?

Rachel

-

Duncan

- Candidate for Boat-Obsession Medal

- Posts: 388

- Joined: Fri Mar 03, 2006 7:28 am

- Boat Name: Coquine

- Boat Type: Cape Dory 27

- Location: Montréal

- Contact:

Re: Triton Rudder Shaft

Is this one of those "does this rudder make my ass look fat?" questions? ;)Rachel wrote:...The transom/stern area on a CD 28 is pretty "chunky" compared to a Triton. I'm sure anything can be done to anything, but I wonder if it would work out anywhere near as well or easily on a Triton with it's more svelte shape in that area?

I see what you mean, from the side views of both designs, but I don't think the extra overhang on the "svelte" Triton would make any difference, since the overhang is aft of the rudder attachment point:

It wasn't a huge project for Fred, but he's a shipwright, I would say, so this would still be quite a challenge for those of us who are far less experienced.

Cape Dory 10 & 27

-

Triton106

- Candidate for Boat-Obsession Medal

- Posts: 392

- Joined: Fri Apr 18, 2003 4:51 pm

- Location: San Francisco Bay Area

Re: Triton Rudder Shaft

Thanks Duncan for your interesting idea. The spade rudder design on an Alberg is daring and innovative. In addition to better steering I believe it also aids in reducing weatherhelm since moving the rudder further aft effectively moves the center of lateral resistance aft.

On the other hand, I like the original design for two reasons. One is what Rachel already mentioned which is that a rudder that is attached to a full keel is more protected. The second reason is more personal, I just like the look of the attached rudder.

I have already decided to reuse the rudder since it is in a good condition and is Alberg's Mark II design (i.e. looks like a constellation rudder). The design options I am weighing are more tactical like if I should use lag bolts as in the original design. Should I add a couple of ears as Tim has done, Should I use no lag bolts and just weld two large "ears" that cover the lower part of the rudder shaft. This design came from what my friend Rob did for another Triton owner. It does look extremely strong albeit very heavy. In any case I will have a lot of time to think about it now that I have another rudder to play with.

On the other hand, I like the original design for two reasons. One is what Rachel already mentioned which is that a rudder that is attached to a full keel is more protected. The second reason is more personal, I just like the look of the attached rudder.

I have already decided to reuse the rudder since it is in a good condition and is Alberg's Mark II design (i.e. looks like a constellation rudder). The design options I am weighing are more tactical like if I should use lag bolts as in the original design. Should I add a couple of ears as Tim has done, Should I use no lag bolts and just weld two large "ears" that cover the lower part of the rudder shaft. This design came from what my friend Rob did for another Triton owner. It does look extremely strong albeit very heavy. In any case I will have a lot of time to think about it now that I have another rudder to play with.

Ray D. Chang

Triton 106 in Berkeley, CA

Triton 106 in Berkeley, CA